Recently, Meacon reached a cooperation agreement with Dongfeng Honda Automobile Co., Ltd., the first enterprise in the history of Hubei Province with an annual output value exceeding one billion, to provide process automation solutions for its second factory.

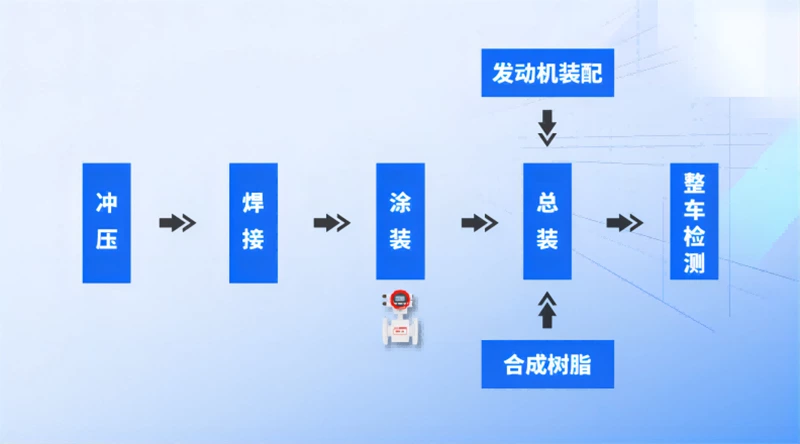

Dongfeng Honda's second factory is the benchmark factory of Honda globally, covering an area of 1.05 million square meters. It integrates many advanced production equipment and industry-leading production processes, including stamping, welding, painting, synthetic resin, engine assembly, final assembly, and vehicle testing in seven major process production lines. In this collaboration, products solutions such as Meacon electromagnetic flow meters are mainly applied to the painting process production line to achieve precise energy consumption measurement and energy management.

According to Tang Junfeng, the head of the Meacon Wuhan office, the painting workshop plays a crucial role in automotive manufacturing, being a key link in the appearance quality and painting efficiency of automobiles. In the second factory of Dongfeng Honda, Meacon's flow solution can help customers achieve precise flow measurement and control, reducing costs, improving production efficiency, and fulfilling environmental responsibilities more scientifically. "Customers are quite satisfied with both product performance and service timeliness, and have expressed that they will promote it in other processes and factories in future cooperation, replacing imports," Tang Junfeng said.

The pressure, temperature, flow, level, analysis, and display solutions provided by Meacon have been widely and deeply applied throughout the entire industry chain and all process flows in the automotive industry. It has successively served well-known domestic and foreign enterprises such as BYD, Tesla, Mazda, Geely, CATL, and empowered customers and the industry for high-quality development.