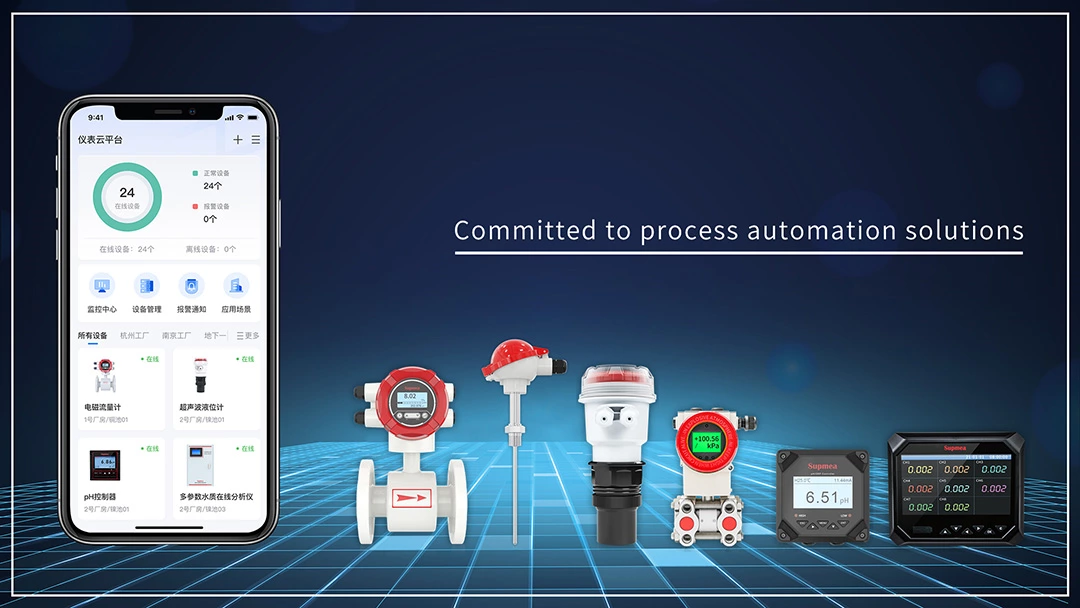

Instrument + cloud, everything has changed!

"In the past, our staff had to frequently climb to high places to check instrument data, which was not only time-consuming and labor-intensive, but also inefficient and involved certain safety risks. But now, everything has changed !" said Mr. Huang.

The chemical company where Mr. Huang works is located in Mianzhu City, Sichuan Province. It has a development history of more than 20 years and focuses on the production and storage management of chemical products.

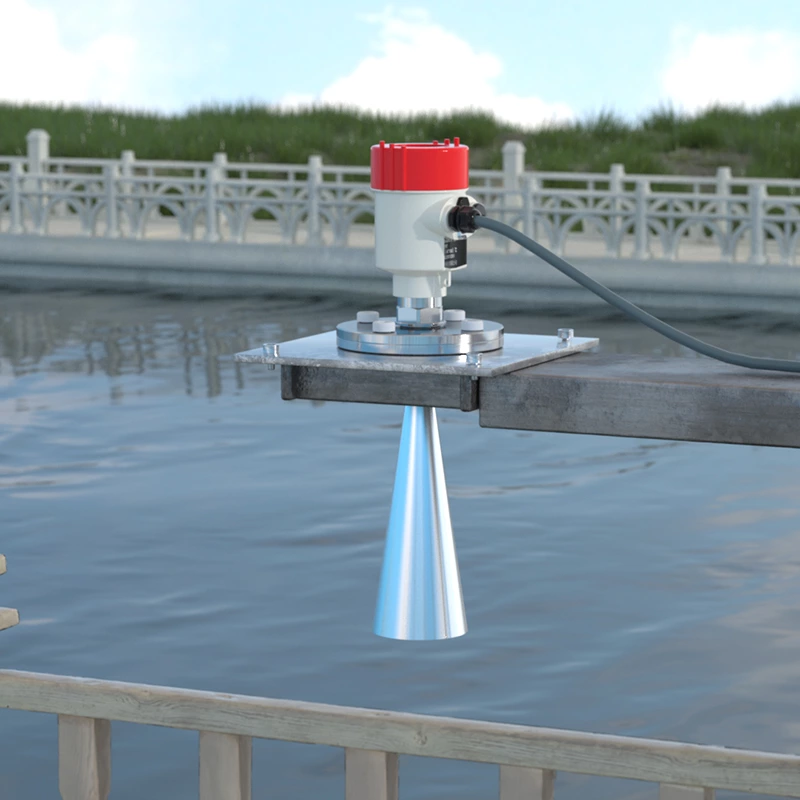

Back in May 2024, this chemical company decided to purchase a batch of domestic instruments to replace old imported equipment. The 15 radar level meters from Meacon became the "icebreakers" and took on the important task of level measurement in chemical storage tanks.

“At the beginning, I was really curious about the performance of this batch of domestic instruments.” Engineer Huang smiled as he recalled the days when these radar level meters were installed.

One month passed quickly, and these 15 radar level meters were "unexpectedly accurate and stable ." In addition to the replacement of imported instruments with domestic ones, what Huang could not have imagined was that a return call from Meacon completely overturned their existing working methods.

During the follow-up call, Mr. Huang inadvertently revealed a small problem in daily management: " It is a bit troublesome to view, manage and analyze instrument data. A large amount of data needs to be summarized and recorded manually every day, and then analyzed. The whole process is time-consuming and inefficient. It would be great if this problem could be solved."

Meacon team brought hope to Mr. Huang - an invitation to try the Instrument Cloud solution . It took only two days from the end of the communication to receiving the Instrument Cloud IoT module.

"It's really a revolutionary experience." Huang excitedly described the changes after connecting to the instrument cloud - people in the office can directly see the real-time liquid level of the storage tank through their mobile phones or computers, without having to go to the site. More importantly, by setting alarm values, the system automatically analyzes data and notifies you of abnormal situations as soon as possible, greatly reducing safety risks and the possibility of production delays.

Meacon's Digital Business Department revealed that after in-depth application experience of the "instrument + cloud platform", the chemical enterprise customer recently ordered another batch of equipment and plans to carry out further cooperation with Meacon to promote comprehensive domestic substitution and digital transformation.

“From ‘looking far ahead’ to ‘cloud-based intelligent control’, what we expect to see is not only the optimization of our customers’ working methods, but also the transformation to improve quality, reduce costs and increase efficiency through digital transformation . Let customers in more industries feel that everything has changed !”