Meacon helps this dyeing and finishing company to have a clear idea of what is going on

Editor's note: In the printing and dyeing workshop of a key textile enterprise in Jinhua City, a silent transformation is taking place. How does Meacon's process automation solution help this enterprise further achieve its energy conservation and emission reduction goals? And how does it help the enterprise move towards a greener and more efficient future through data-driven methods? Let's find out.

“ The dyeing and finishing industry is a typical energy-intensive industry, involving a large amount of water, electricity, steam and other energy consumption.

Therefore, energy saving, emission reduction and consumption reduction have become the core problems that dyeing and finishing enterprises must face and overcome in the process of refined management. " said Luo Gong, a senior engineer in Fujian, Zhejiang and Shanghai of Meacon.

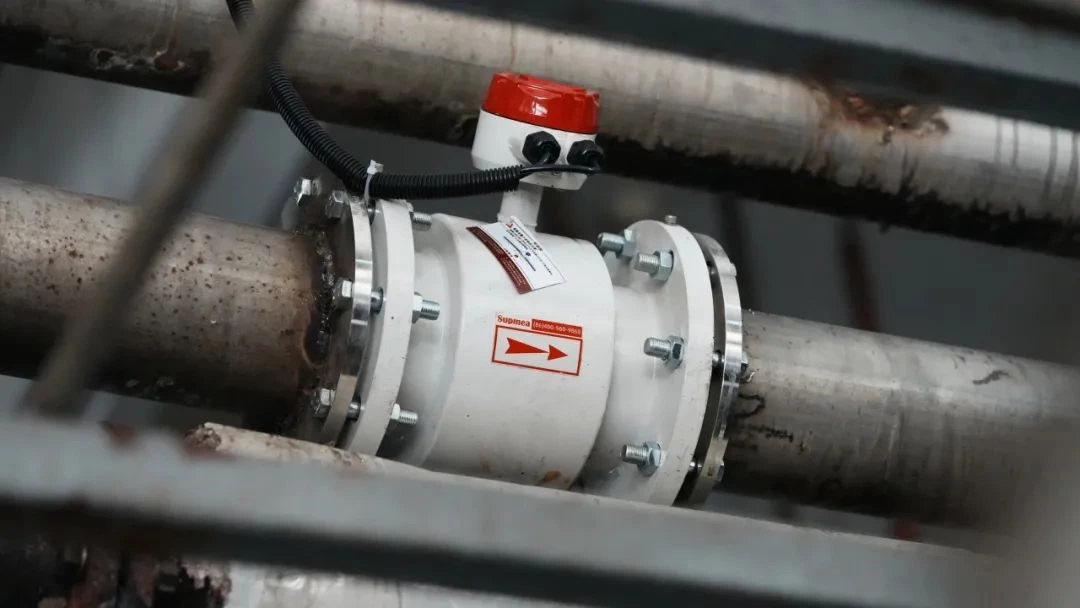

Recently, more than 100 sets of flow, pressure, temperature and other process automation instruments produced by Meacon have been used in the printing and dyeing workshop of a key textile enterprise in Jinhua, providing strong support for its three-level energy consumption management system.

Mr. Luo introduced that in this cooperation, Meacon customized a complete energy consumption management system based on the special needs of the customer's printing and dyeing workshop , which can monitor the energy consumption of key equipment such as dyeing machines, printing machines, and dryers in real time.

"With the help of this system, customers can quickly locate which equipment or process flows have energy waste problems and take corresponding technical improvements or management measures accordingly," said Mr. Luo.

The person in charge of the printing and dyeing workshop revealed that in the past, the energy consumption statistics of the workshop mainly relied on manual recording, which was not only time-consuming and labor-intensive, but also prone to errors. "Now, we have not only greatly saved human resources , but more importantly, we have achieved precise control of the production process ."

Through comprehensive analysis of massive energy consumption data, enterprises can also accurately identify potential energy-saving areas and formulate more scientific and reasonable production plans.

" Data-driven decision-making is undoubtedly more scientific and efficient. We are using this data to continuously optimize production processes to ensure that every bit of energy is used most effectively," the person in charge added.

After years of hard work, Meacon has a deep understanding of the dyeing and finishing industry and has accumulated rich practical experience. "We look forward to working hand in hand with more partners to promote the development of dyeing and finishing enterprises in the direction of green, intelligent and efficient, and contribute to the construction of a green manufacturing system." said Luo Gong.