A high-temperature pressure transmitter is a specialized device used to measure and transmit pressure readings in applications where the temperature is significantly elevated. These transmitters are designed to withstand and function reliably under extreme temperature conditions, ensuring accurate pressure measurements even in harsh environments.

Features of a High-Temperature Pressure Transmitter:

1. Temperature Resistance: These transmitters are constructed using materials that can withstand high temperatures without compromising accuracy or performance.

2. High Pressure Range: They are capable of measuring pressures across a wide range, making them suitable for various industrial processes and applications.

3. Stability and Reliability: High-temperature pressure transmitters are engineered to maintain stability and accuracy over prolonged periods of operation, even in challenging conditions.

4. Protective Enclosure: To shield sensitive internal components from extreme temperatures and potential contaminants, they often come with a robust protective enclosure.

5. Output Signals: These transmitters typically offer various output options, such as analog signals (4-20mA, 0-5V, etc.) or digital protocols (HART, Profibus, Foundation Fieldbus, etc.), allowing seamless integration with control systems.

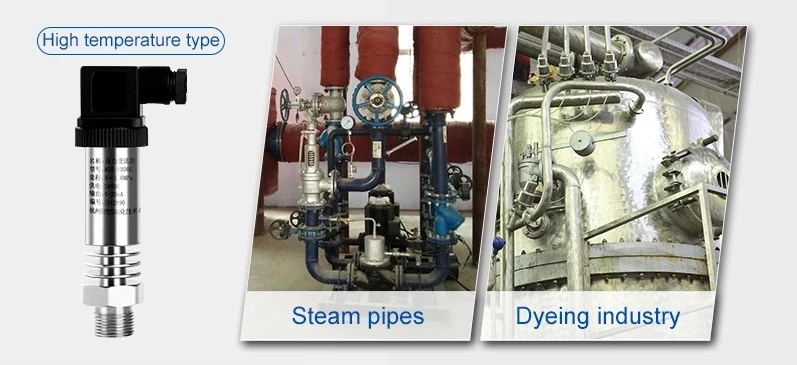

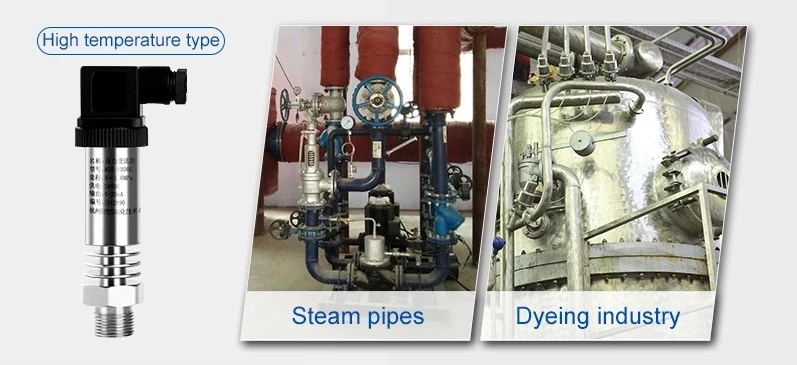

Applications:

High-temperature pressure transmitters find applications in industries like:

1. Petrochemicals: They are used in refining and processing plants where high-temperature and high-pressure conditions are common.

2. Power Generation: In power plants, these transmitters help monitor boiler and steam pressures at elevated temperatures.

3. Aerospace: In aircraft and spacecraft, where temperature variations can be extreme, these transmitters ensure proper pressure measurements.

4. Metallurgy: For monitoring pressure in high-temperature furnaces and metal casting processes.

5. Oil & Gas: In upstream and downstream operations where processes involve high temperatures and pressures.

6. Automotive: Some automotive testing and research applications require pressure measurements at high temperatures.

It's important to note that the specific capabilities and temperature ranges of high-temperature pressure transmitters may vary among manufacturers and models, so it's essential to choose a transmitter that best suits the requirements of the particular application.

| Product |

High temperature Pressure transmitter |

| Model |

MIK-P300G |

| Measuring range |

-0.1…0/0.01…60Mpa |

| Display resolution |

0.5% |

| Medium temperature |

-50-300°C |

| Working temperature |

-20-85°C |

| Output signal |

4-20mA Analog output |

| Pressure type |

Gauge pressure, adiabatic pressure and sealed pressure |

| Measure medium |

Liquid; Gas; Oil etc. |

| Pressure overload |

0.035...10MPa (150%FS)10...60MPa (125%FS) |

| Power supply |

10-32V (4...20mA);12-32V (0...10V);8-32V (RS485) |

MIK-P300G High-temperature pressure transmitter is a specialized device designed to accurately measure and monitor extreme conditions in industrial applications. These transmitters are built to withstand harsh environments and can operate at temperatures and pressures beyond the range of standard sensors.

High temp pressure transmitters are typically constructed using high-quality materials such as ceramic or stainless steel to ensure durability and reliability. They can be used in various applications, including in thermal power plants, petrochemical plants, and aerospace industries, to measure critical parameters such as pressure, temperature, and flow rates. With their ability to withstand extreme conditions, high temp pressure transmitters play a critical role in ensuring the safe and efficient operation of these industrial processes.

High-temperature pressure sensors are available in a range of configurations, including gauge, absolute, and differential pressure sensors. Gauge sensors measure pressure relative to atmospheric pressure, while absolute sensors measure pressure relative to a vacuum. Differential pressure sensors measure the difference in pressure between two points.

In addition to their use in industrial applications, high-temperature pressure sensors are also used in the aerospace industry and in research and development settings. These sensors play a critical role in ensuring the safety and efficiency of many processes and systems.