10 Things to Consider Before Selecting Flow Meters

1. Type of Fluid

The type of fluid being measured plays a significant impact on the selection of flow meters, as different types of fluids can have different properties that affect the flow measurement. For example, fluids with high viscosity or high solids content may require a different type of flow meter than fluids with low viscosity or low solids content.

One important consideration when selecting a flow meter is the chemical compatibility of the flow meter materials with the fluid being measured.

Certain fluids may be corrosive or abrasive, and if the flow meter is not designed to handle these fluids, it can lead to inaccurate readings or damage to the flow meter.

Another important consideration is the temperature and pressure of the fluid being measured. Some flow meters may not be able to handle high temperatures or pressures, which can limit their use in certain applications.

The properties of the fluid being measured can also affect the accuracy and reliability of the flow measurement. For example, certain flow meters may be more accurate for fluids with a consistent viscosity, while others may be more accurate for fluids with varying viscosity. Similarly, the presence of bubbles or solids in the fluid can also affect the accuracy of some flow meters.

Therefore, selecting the right flow meter for the specific fluid being measured is important to ensure accurate and reliable flow measurements. It is important to consult with a flow meter expert or supplier to ensure that the flow meter is designed to handle the specific properties of the fluid and the conditions of the application. You can get free technical support at Supmea. Contact now.

2. Flow Rate Range

The flow rate range is an important consideration when selecting a flow meter, as different flow meters have different operating ranges and are optimized for different flow rates. Selecting the wrong flow meter for a given flow rate range can lead to inaccurate readings, reduced accuracy, and increased maintenance and operating costs.

For example, if the flow rate range is relatively low, such as less than 1 liter per minute, a positive displacement flow meter or a turbine flow meter may be a good choice. These flow meters are highly accurate at low flow rates and are ideal for precise measurement and control of low-flow applications.

On the other hand, if the flow rate range is relatively high, such as greater than 100 liters per minute, an electromagnetic flow meter or an ultrasonic flow meter may be a better choice. These flow meters are optimized for high-flow applications and can provide accurate and reliable measurements at high flow rates.

In addition to the flow rate range, other factors such as the type of liquid being measured, the pipe size and material, and the desired level of accuracy and reliability also need to be considered when selecting a flow meter. It is important to consult with a flow meter expert or supplier to ensure that the right flow meter is selected for the specific application and a flow rate range.

3. Accuracy Requirements

The accuracy and level of calibration required for different flow meters can vary depending on the specific type of flow meter and the application in which it is being used. Some common types of flow meters and their typical accuracy and calibration requirements include:

Electromagnetic flow meters: The electromagnetic flow meters are highly accurate, typically with an accuracy of ±0.5% to ±1% of the measured flow rate. They require periodic calibration to ensure accurate readings.

Ultrasonic flow meters: The ultrasonic flow meters have a wide operating range and can be highly accurate, typically with an accuracy of ±1% to ±2% of the measured flow rate. They require periodic calibration to ensure accurate readings.

Turbine flow meters: These flow meters are highly accurate at low to medium flow rates, typically with an accuracy of ±0.5% to ±1% of the measured flow rate. They require periodic calibration to ensure accurate readings.

Coriolis flow meters: The Coriolis flow meters are highly accurate and can provide direct mass flow measurements, typically with an accuracy of ±0.1% to ±0.5% of the measured flow rate. They require less frequent calibration compared to other flow meters.

Positive displacement flow meters: These flow meters are highly accurate at low flow rates, typically with an accuracy of ±0.5% to ±1% of the measured flow rate. They require periodic calibration to ensure accurate readings.

The level of calibration needed for different flow meters can also depend on the specific application in which they are being used. For example, in critical applications where high accuracy is required, flow meters may need to be calibrated more frequently to ensure accurate readings. Additionally, factors such as changes in temperature or pressure can affect the accuracy of flow meters and may require recalibration.

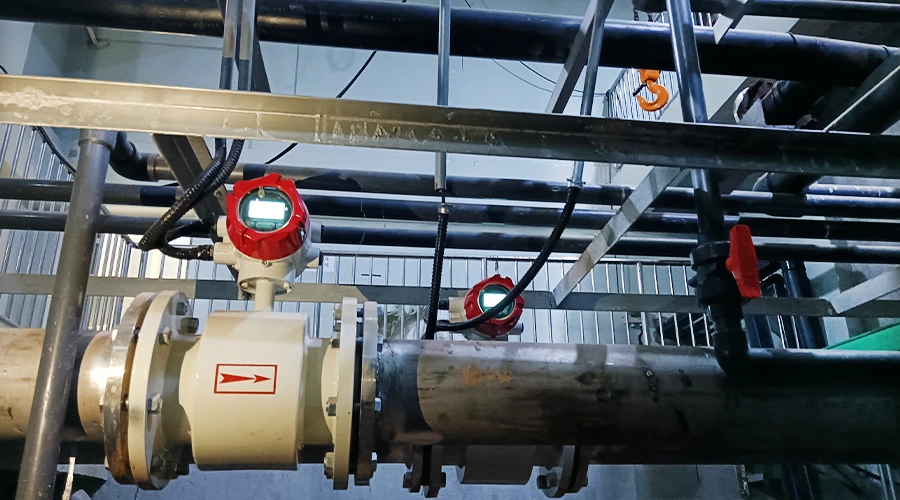

4. Installation Requirements

The orientation and size of the pipe, as well as the need for straight pipe runs and access to the flow meter for maintenance can all have an impact on the selection of flow meters.

Pipe orientation and size: The orientation and size of the pipe can impact the selection of flow meters because different types of flow meters are designed to work with different pipe sizes and orientations. For example, some flow meters are designed to work with vertical pipe runs, while others may be better suited for horizontal or angled pipe runs. Similarly, the diameter of the pipe can affect the accuracy and reliability of the flow measurement, and certain types of flow meters may be better suited for larger or smaller pipe sizes.

Straight pipe runs: The need for straight pipe runs before and after the flow meter can also impact the selection of flow meters. Many types of flow meters require a certain length of straight pipe before and after the meter to ensure an accurate and stable flow measurement. If there is limited space for straight pipe runs, or if the flow meter cannot be installed in a straight section of pipe, alternative flow meters may need to be considered.

Access for maintenance: The need for access to the flow meter for maintenance and calibration can also impact the selection of flow meters. Some flow meters may require regular maintenance or calibration, and if the flow meter is located in a difficult to access location, it can make maintenance and calibration more difficult and time-consuming. In these cases, flow meters that are easier to access and maintain may be preferred.

In a word, it is important to consider the orientation and size of the pipe, as well as the need for straight pipe runs and access for maintenance, when selecting a flow meter to ensure that the flow meter is suitable for the specific installation requirements and can provide accurate and reliable flow measurements.

5. Pressure and Temperature Limitations

Pressure and temperature limitations play a momentous impact on the selection of flow meters as different types of flow meters are designed to work within the specific pressure and temperature ranges.

Pressure limitations: The pressure of the fluid being measured can impact the selection of flow meters because some flow meters may not be able to operate at high pressures or may require additional pressure-reducing equipment to be installed. In some cases, the pressure limitations of the flow meter may be a critical factor in the selection process.

Temperature limitations: The temperature of the fluid being measured can also impact the selection of flow meters because some flow meters may not be able to operate at high temperatures or may require additional insulation or cooling equipment to be installed. In some cases, the temperature limitations of the flow meter may be a critical factor in the selection process.

Material compatibility: The pressure and temperature of the fluid being measured can also impact the selection of flow meters because different materials may be required to withstand the specific conditions. For example, some types of fluids may require flow meters made of specific materials that are resistant to corrosion or erosion caused by the fluid.

Accuracy limitations: The pressure and temperature of the fluid being measured can also impact the accuracy and reliability of the flow meter. Some types of flow meters may be more accurate at a certain pressure and temperature ranges than others, and in some cases, additional calibration may be required to ensure accurate and reliable flow measurements.

Substantially, it is important to consider the pressure and temperature limitations when selecting a flow meter to ensure that the flow meter is suitable for the specific installation requirements and can provide accurate and reliable flow measurements. It is also important to consult with a flow meter expert or supplier to ensure that the flow meter is designed to handle the specific properties of the fluid and the conditions of the application.

6. Signal Output

Determine the required signal output, such as analog or digital, and whether the flow meter needs to interface with other equipment or control systems.

The signal output of a flow meter can impact the selection process in several ways, and it is important to consider the requirements of the application to determine the most suitable signal output. Here are some specific considerations:

Analog or digital output: Flow meters can provide analog or digital outputs, and the selection depends on the requirements of the application. Analog signals are typically used for simple applications where real-time measurements are required, while digital signals are more suitable for applications that require advanced data logging and analysis.

Pulse output: Many flow meters provide pulse outputs that are used to calculate the flow rate based on the number of pulses received over a specific time interval. The pulse output is typically used in applications where flow rate measurements are required for billing purposes, and it is important to select a flow meter that provides a pulse output with a suitable frequency.

Communication protocols: Some flow meters provide communication protocols such as Modbus, HART, or Profibus, which are used to connect the flow meter to a control system or network. The selection of a flow meter with a suitable communication protocol depends on the requirements of the application and the compatibility with the existing control system or network.

Output range: The output range of a flow meter refers to the maximum and minimum values that can be measured by the flow meter. It is important to select a flow meter with an output range that is suitable for the expected flow rates in the application to ensure that the flow meter can provide accurate and reliable measurements.

By and large, the signal output of a flow meter is an important consideration when selecting a flow meter, as it determines how the flow meter will be integrated into the control system and how the data will be analyzed and processed. It is important to consult with a flow meter expert or supplier to determine the most suitable signal output for the specific requirements of the application.

7. Maintenance Requirements

Maintenance requirements are an important consideration when selecting a flow meter, as they can impact the overall cost of ownership and the reliability of the flow meter over time. Here are some specific ways that maintenance requirements can affect the selection of flow meters:

Access for maintenance: Some flow meters require periodic calibration or cleaning, and it is important to consider the accessibility of the flow meter for maintenance purposes. For example, a flow meter that is installed in a difficult-to-reach location may require additional time and expense to perform maintenance, which can increase the overall cost of ownership.

Maintenance frequency: The frequency of maintenance required for a flow meter can vary depending on the type of flow meter, the type of fluid being measured, and the conditions of the application. It is important to select a flow meter with a maintenance frequency that is suitable for the specific requirements of the application, as frequent maintenance can increase downtime and costs.

Ease of maintenance: Some flow meters are designed to be easy to maintain, with user-replaceable components and simple calibration procedures. It is important to consider the ease of maintenance when selecting a flow meter, as it can impact the overall cost and reliability of the flow meter over time.

Spare parts availability: Availability of spare parts can also impact maintenance requirements for flow meters. It is important to select a flow meter with spare parts that are readily available, so that maintenance can be performed quickly and easily.

In general, the maintenance requirements of a flow meter can impact the overall cost of ownership and reliability of the flow meter over time. It is important to consider these factors when selecting a flow meter, and to consult with a flow meter expert or supplier to determine the most suitable flow meter for the specific requirements of the application.

8. Power Source

Determine the power source required for the flow meter, such as battery or AC power, and whether it needs to be installed in a hazardous or explosive environment.

The power source is an important consideration when selecting a flow meter, as it can impact the installation, operation, and maintenance of the flow meter. Here are some specific ways that the power source can affect the selection of flow meters:

Availability of power source: The availability of a power source can be a critical factor in the selection of a flow meter. Some flow meters require a specific type of power source, such as AC or DC power, and it is important to ensure that the required power source is available at the installation site.

Power consumption: The power consumption of a flow meter can impact the overall operating cost of the flow meter. Some flow meters require more power than others to operate, and it is important to consider the power consumption of the flow meter when selecting a flow meter.

Battery life: If a flow meter is powered by batteries, the battery life can impact the maintenance requirements of the flow meter. It is important to select a flow meter with a battery life that is suitable for the specific requirements of the application, as frequent battery replacement can increase the overall cost of ownership.

Power source reliability: The reliability of the power source can impact the overall reliability of the flow meter. For example, if the power source is prone to fluctuations or interruptions, it can impact the accuracy and consistency of the flow meter readings. It is important to select a flow meter with a power source that is reliable and stable.

Overall, the power source is an important factor in the selection of a flow meter. It is important to consider the availability, power consumption, battery life, and reliability of the power source when selecting a flow meter, and to consult with a flow meter expert or supplier to determine the most suitable flow meter for the specific requirements of the application.

9. Cost

Think about the cost of the flow meter and its associated installation and maintenance costs, and compare it to the budget available for the project.

Cost carries weight with selecting a flow meter, as it can impact the overall budget and cost of ownership.

Initial cost: The initial cost of a flow meter can vary widely depending on the type of flow meter and the features and capabilities it offers. It is important to consider the initial cost of the flow meter when selecting a flow meter, and to balance the cost against the benefits and features that are required for the specific application.

Operating cost: In addition to the initial cost, the operating cost of a flow meter can also impact the selection. For example, some flow meters may require frequent calibration, cleaning, or maintenance, which can increase the overall operating cost of the flow meter. It is important to consider the operating cost of the flow meter over its expected lifespan when selecting a flow meter.

Cost of installation: The cost of installation can also impact the selection of a flow meter. For example, some flow meters may require specialized tools or expertise for installation, which can increase the overall cost of installation. It is important to consider the cost of installation when selecting a flow meter, and to ensure that the installation is done properly to ensure accurate and reliable flow measurements.

Cost of ownership: The cost of ownership is the total cost of the flow meter over its expected lifespan, including the initial cost, operating cost, and maintenance and repair costs. It is important to consider the cost of ownership when selecting a flow meter, and to choose a flow meter that offers the best balance of cost and performance for the specific requirements of the application.

Generally speaking, cost is an important consideration when selecting a flow meter. It is important to balance the initial cost, operating cost, cost of installation, and cost of ownership against the benefits and features that are required for the specific application, and to consult with a flow meter expert or supplier to determine the most suitable flow meter for the specific requirements and budget.

10. Manufacturer Support

Evaluate the level of support and service provided by the flow meter manufacturer, including availability of spare parts, technical support, and warranty options.

The manufacturer support is an important consideration when selecting a flow meter, as it can impact the performance, reliability, and longevity of the flow meter.

Technical support: The quality and availability of technical support can impact the selection of a flow meter. A manufacturer that offers comprehensive technical support, including phone and email support, online resources, and on-site support, can help ensure that any issues or questions are quickly and effectively addressed, reducing downtime and improving overall performance.

Training and education: The availability of training and education resources can also impact the selection of a flow meter. A manufacturer that offers training and education resources, such as webinars, videos, and on-site training, can help ensure that users are properly trained and knowledgeable about the operation and maintenance of the flow meter, reducing the risk of errors and increasing the longevity of the flow meter.

Warranty and repair services: The warranty and repair services offered by the manufacturer can also impact the selection of a flow meter. A manufacturer that offers a comprehensive warranty, as well as repair and replacement services, can help ensure that any issues or failures are quickly and effectively resolved, reducing downtime and minimizing the overall cost of ownership.

Upgrade and replacement options: Finally, the upgrade and replacement options offered by the manufacturer can impact the selection of a flow meter. A manufacturer that offers upgrade options, such as software upgrades or sensor replacements, can help extend the lifespan of the flow meter and improve its performance over time. Additionally, a manufacturer that offers replacement options, such as trade-in programs or buyback programs, can help reduce the overall cost of ownership and improve the ROI of the flow meter.

Then, the manufacturer support is an important consideration when selecting a flow meter. It is important to choose a manufacturer that offers comprehensive technical support, training and education resources, warranty and repair services, and upgrade and replacement options, to ensure the best possible performance, reliability, and longevity of the flow meter.

All things considered, Flow meter selection is an important consideration for purchasers, as it can impact the performance, reliability, and cost-effectiveness of the system or process being monitored. Hence it is important for purchasers to carefully evaluate the requirements of their system or process, as well as the features and capabilities of different flow meters, to ensure the best possible performance and ROI.

Supmea is committed to developing innovative flow meters that work with the most demanding liquid, steam, and air flow measurements. Find high-accuracy and competitive price flow meters at Supmea. Do not hesitate to inquire now.