Main points for maintenance of electromagnetic flowmeter

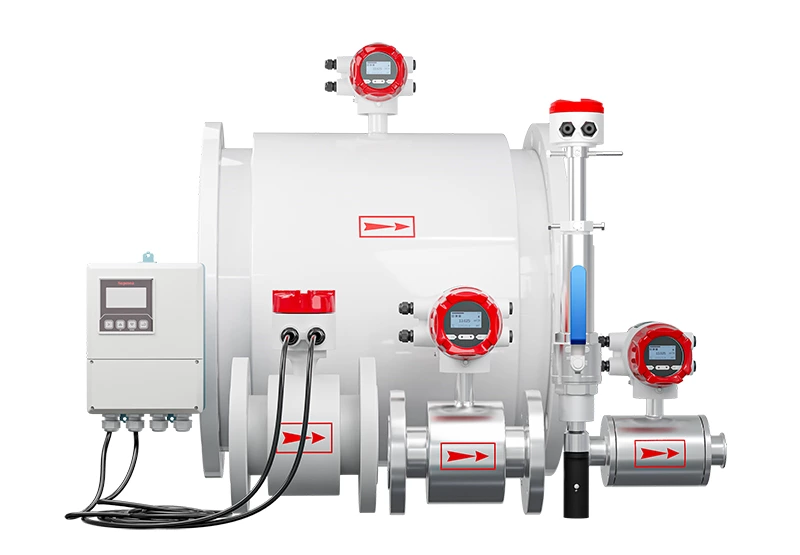

Electromagnetic flowmeter is one of the most commonly used medium measuring instruments in industrial production. Through electromagnetic flowmeter, we can measure the quality, flow rate and other data of the medium to analyze whether the production process is normal. In industrial environment, electromagnetic flowmeter is generally used for measuring some corrosive media, so it needs to be regularly maintained during use to ensure its normal operation.

When the electromagnetic flowmeter is powered on, the zero point must be adjusted when the electromagnetic flow sensor is filled with liquid and in a static state. After it is put into operation, the flow should be stopped regularly to check the zero point according to the application conditions; especially for accumulation, easy to contaminate electrodes, and non-clean liquids rich in solids, more inspections should be carried out in the early stage of operation to determine the normal inspection cycle. Compared with rectangular wave excitation, electromagnetic flowmeters with AC excitation are more prone to zero drift, so more attention should be paid to inspection and adjustment.

After the electromagnetic flowmeter is shut down, it is necessary to measure the resistance between the electrodes first, then disconnect the signal connection between the sensor and the converter, and measure whether the instrument is within the manufacturer's specified value range after being filled with liquid. Each measured resistance value needs to be recorded and saved, which can be used as a basis for judging electromagnetic flowmeter sensor failure in the future.