Reference for selection of radar level gauges for different media

In industrial production, in order to ensure that products meet quality requirements,various instruments and equipment are needed to help better control the production process.Among them,radar level meters are fully used in the production process.Under different working conditions,it is particularly important to choose a suitable radar level meter.

1. Treatment methods for different media

Guided wave radar should be preferred for the medium with low dielectric constant and variable dielectric constant. The signal of low dielectric constant liquid medium itself is relatively weak, so it is necessary to emit a strong electromagnetic wave signal and use a powerful microprocessor for complex signal processing. The difference between guided wave radar and conventional radar is only the difference in signal amplitude or intensity. Other functions are the same, and guided wave radar only needs to measure the transmission time of electromagnetic waves, without signal processing and identification.

2. Solid material measurement method

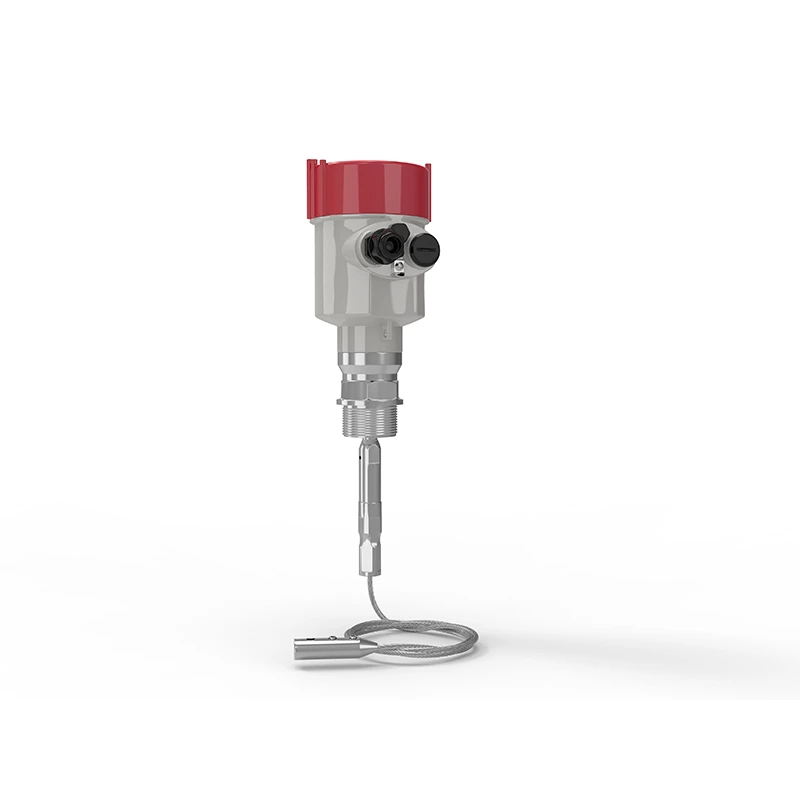

When the medium to be measured is a powdery material , a cable-type guided wave radar can be selected. Since microwaves are transmitted in the steel cable, the dust generated during the material transportation process has no effect on the measurement. When the measured medium is a granular or blocky material, a high-frequency radar level meter must be selected, and the smaller the microwave emission angle, the better, because the microwave frequency is completely inversely proportional to its wavelength, so this can be used well for measurement.

3. Liquid and level measurement methods

For tanks with relatively stable liquid levels and high dielectric constants of the measured liquid, ordinary radar level meters can be selected ; for tanks with large liquid level fluctuations , stirring, or low dielectric constants of the measured liquid, waveguide radars should be preferred. The waveguide will have a certain effect on the liquid surface, and its microwave reflection will basically not be affected by the external environment , thus ensuring the stability and accuracy of the measurement results.

The above are several reference points when selecting a radar level meter . In addition, basic settings should be made for the instrument, such as setting the tank characteristics according to the shape of the tank measured by the level meter , setting the dielectric constant according to the characteristics of the detected medium , selecting the process changes of the measured medium in the process conditions , and if it is a rod-type radar level meter, the contact condition of the bottom of the probe should also be set.