Reliable Radar Level Measurement Solutions

Radar level measurement is a widely used technology in various industries to accurately and reliably measure the level of liquids and solids in tanks, vessels, and other containers. With its non-contact nature and ability to perform in challenging environments, radar level measurement solutions have become the go-to choice for many applications. In this article, we will explore the benefits, types, key features, industry applications, factors to consider, case studies, and future trends of reliable radar level measurement solutions.

Introduction

Radar level measurement is a technique that uses radar waves to determine the level of a substance in a container. It relies on the principle of time-of-flight, where the radar wave is emitted from a transmitter, reflects off the surface of the substance, and returns to a receiver. By measuring the time taken for the wave to travel, the distance to the surface can be calculated, providing an accurate level measurement.

What is Radar Level Measurement?

Radar level measurement is a technique used to determine the level of a substance (liquid, solid, or slurry) in a container or vessel. It relies on the principle of radar technology, which uses electromagnetic waves to measure distances.

In radar level measurement, a radar sensor or transceiver is mounted on top of the container or vessel. The sensor emits short pulses of high-frequency electromagnetic waves, typically in the microwave range, which then travel downward towards the substance being measured. When these waves encounter the surface of the substance, they reflect back towards the sensor.

The radar sensor measures the time it takes for the waves to travel to the substance's surface and back. By knowing the speed of the waves in the medium (which is usually air), the sensor can calculate the distance from the sensor to the substance's surface. This distance corresponds to the level of the substance in the container.

Radar level measurement offers several advantages. It is a non-contact method, meaning there is no physical contact between the sensor and the substance being measured. This makes it suitable for measuring corrosive or hazardous materials. It is also unaffected by changes in temperature, pressure, or the physical properties of the substance.

Additionally, radar level measurement can provide accurate and reliable measurements even in challenging conditions, such as high temperatures, dust, vapor, or foam. It is commonly used in various industries, including oil and gas, chemical processing, water treatment, food and beverage, and pharmaceuticals, for applications such as inventory management, process control, and safety monitoring.

Benefits of Radar Level Measurement Solutions

Accurate and reliable measurements

Radar level measurement solutions offer high accuracy, often within millimeter-level precision. They provide reliable measurements even in conditions where other technologies may struggle, such as in the presence of foam, vapor, or turbulent surfaces. This accuracy and reliability are crucial in industries where precise level control is essential for process optimization and safety.

Non-contact measurement

Unlike invasive measurement techniques that require direct contact with the substance being measured, radar level measurement is non-contact. This means there is no physical contact between the radar sensor and the substance, eliminating the risk of contamination or damage to the sensor. Non-contact measurement also enables radar sensors to be used in applications where hygiene or sterile conditions are critical.

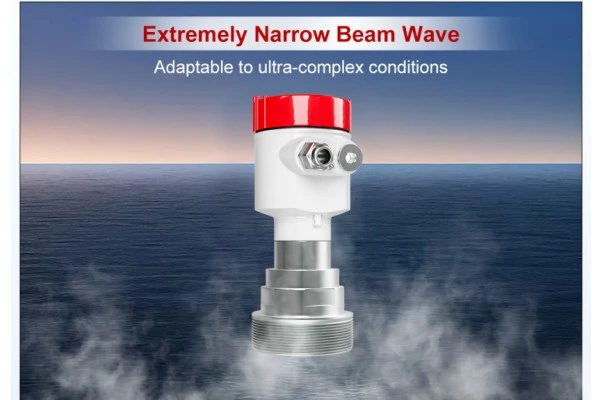

Suitable for challenging environments

Radar level measurement solutions are designed to withstand harsh environments. They can operate reliably in extreme temperatures, high pressures, corrosive or abrasive media, and even in areas prone to vibration or electromagnetic interference. This robustness makes radar level measurement suitable for a wide range of industries, including oil and gas, chemical processing, and wastewater treatment.

Wide application range

Radar level measurement solutions can be applied to various substances, from liquids and slurries to granular materials and powders. They are used in diverse industries, such as oil and gas production, chemical manufacturing, water treatment, food and beverage processing, pharmaceuticals, and mining. The versatility of radar level measurement makes it an indispensable tool in many sectors.

Types of Radar Level Measurement Solutions

There are several types of radar level measurement solutions available, each with its own characteristics and applications. Let's explore some of the common types:

Guided Wave Radar

Guided wave radar (GWR) uses a probe or cable that extends into the substance being measured. The radar signal travels along the probe, and the change in impedance at the interface between the probe and the substance is detected. GWR is particularly useful for measuring levels in liquids, as the probe can also detect interface levels and provide continuous measurements even with changing process conditions.

Non-Contact Radar

Non-contact radar, also known as free-space radar, operates without physical contact with the substance. It emits radar waves into the vessel and measures the time it takes for the wave to reflect back from the surface. Non-contact radar is suitable for measuring levels of liquids, slurries, and solids, including those with uneven or turbulent surfaces.

Pulse Radar

Pulse radar emits short radar pulses and measures the time it takes for the pulse to return. It is capable of accurately measuring distances and levels, even in challenging conditions. Pulse radar is commonly used in applications where high accuracy and reliability are required, such as custody transfer measurements and inventory management.

Key Features to Consider in Radar Level Measurement Solutions

When selecting a radar level measurement solution, there are several key features to consider. These features will vary depending on the specific application and requirements, but some common considerations include:

Frequency and antenna size

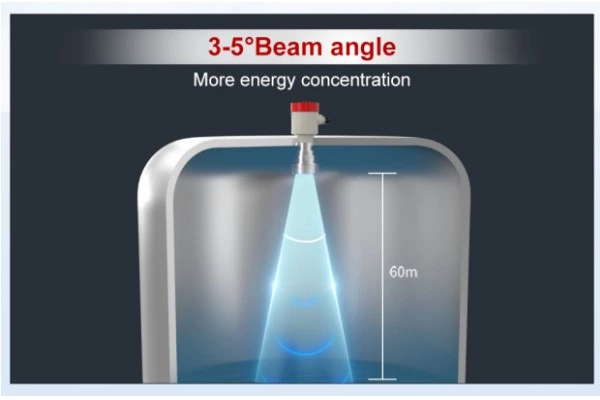

The frequency and antenna size of a radar level measurement system determine its measurement range and accuracy. Higher frequencies and smaller antennas offer better resolution and accuracy for measuring shorter distances, while lower frequencies and larger antennas are suitable for longer-range measurements.

Signal processing capabilities

Advanced signal processing algorithms can improve the reliability and accuracy of radar level measurements. Features like echo tracking, signal averaging, and interference suppression can enhance the measurement performance, especially in challenging environments with obstructions or interfering signals.

Range and accuracy

The measurement range and accuracy of a radar level measurement solution are crucial factors to consider. The range should be able to cover the entire measurement span, including any anticipated variations or fluctuations. Accuracy is typically expressed as a percentage of the measured distance and should align with the specific requirements of the application.

Installation and maintenance requirements

Consider the ease of installation and maintenance when selecting a radar level measurement system. Some systems may require complex setup procedures or frequent calibration, while others offer simple plug-and-play installation and minimal maintenance requirements. Evaluating these factors can help optimize the overall efficiency and cost-effectiveness of the solution.

Industry Applications of Radar Level Measurement

Radar level measurement solutions find applications in various industries where accurate and reliable level measurements are essential for process control, inventory management, and safety. Here are some notable industry applications:

Oil and gas

In the oil and gas industry, radar level measurement is used for inventory management, custody transfer measurements, and overfill protection in storage tanks. It ensures accurate measurement of petroleum products, liquefied gases, and crude oil, even in challenging environments with high pressures, temperatures, or agitated surfaces.

Chemical processing

Radar level measurement is widely employed in chemical processing plants to monitor liquid levels in storage tanks, reactors, and distillation columns. It enables precise control of feedstock, prevents overfilling, and enhances process efficiency. The non-contact nature of radar measurement is particularly advantageous when dealing with corrosive or hazardous chemicals.

Water and wastewater

Water and wastewater treatment facilities utilize radar level measurement for monitoring water levels in reservoirs, basins, and pumping stations. It enables efficient management of water resources, controls the flow of water, and ensures compliance with regulatory requirements. Radar measurement is especially valuable in applications involving foaming, turbulence, or solids content.

Food and beverage

In the food and beverage industry, radar level measurement plays a crucial role in monitoring ingredient levels, controlling batch processes, and ensuring product quality. It is used in storage silos, mixing vessels, and packaging lines to prevent material shortages or overflows, optimize production, and maintain consistent product formulations.

Factors to Consider when Choosing Radar Level Measurement Solutions

When selecting a radar level measurement solution for a specific application, several factors should be taken into account:

Process conditions and requirements

Evaluate the process conditions, such as temperature, pressure, and the nature of the substance being measured. Consider factors like viscosity, density, and dielectric constant, as they can affect the performance of the radar level measurement system. Additionally, define the specific requirements of the application, including measurement range, accuracy, and response time.

Environmental factors

Consider the environmental conditions surrounding the measurement area. Factors like extreme temperatures, humidity, corrosive gases, or dust can impact the performance and longevity of the radar level measurement system. Choose a solution that is designed to withstand these conditions and maintain accuracy and reliability over time.

Integration with existing systems

If the radar level measurement system needs to integrate with existing control or automation systems, ensure compatibility and seamless communication between the devices. Compatibility with industry-standard communication protocols, such as Modbus or Profibus, can simplify integration and facilitate data exchange with other components of the process control system.

Cost-effectiveness

Consider the overall cost-effectiveness of the radar level measurement solution. Assess not only the initial investment, but also factors such as installation costs, maintenance requirements, and potential energy savings. A reliable and accurate solution may have a higher upfront cost but can deliver long-term benefits in terms of operational efficiency and process optimization.

Case Studies: Real-World Examples of Radar Level Measurement Solutions

To illustrate the practical applications of radar level measurement, let's explore a few real-world case studies:

Case Study 1: Oil Storage Terminal

An oil storage terminal required accurate inventory measurements to ensure proper stock management and avoid overfilling or shortages. They implemented guided wave radar level measurement systems in their storage tanks, enabling continuous and reliable level monitoring. The Supmea radar level system provided accurate measurements, even in the presence of agitated surfaces or vapor, and integrated seamlessly with their inventory management software.

Case Study 2: Chemical Reactor

A chemical processing plant needed to monitor the level of a corrosive liquid in a reactor. They opted for a Supmea non-contact radar level measurement solution with a chemically resistant antenna. The system provided accurate measurements, unaffected by the corrosive nature of the substance, and allowed for precise control of the reaction process. The non-contact measurement eliminated the risk of contamination and reduced maintenance requirements.

Case Study 3: Water Treatment Plant

A water treatment plant aimed to optimize their water storage and pumping operations. They implemented pulse radar level measurement systems in their reservoirs and pumping stations. The systems offered accurate measurements, even in the presence of foam or turbulent surfaces, allowing for efficient management of water resources. The data collected from the radar measurements facilitated predictive maintenance and helped identify potential issues before they led to system failures.

Future Trends in Radar Level Measurement

As technology continues to advance, radar level measurement solutions are expected to evolve in several areas:

Enhanced accuracy and resolution

Advancements in signal processing algorithms and hardware capabilities will enable radar level measurement systems to achieve even higher accuracy and resolution. This will allow for more precise level measurements, especially in applications that require millimeter-level accuracy.

Integration with IoT and cloud platforms

Radar level measurement systems are likely to integrate more seamlessly with IoT (Internet of Things) devices and cloud platforms. This integration will enable real-time monitoring, remote access to measurement data, and enhanced analytics capabilities for process optimization and predictive maintenance.

Improved diagnostics and self-monitoring

Future radar level measurement systems may incorporate advanced diagnostics and self-monitoring features. These features will allow the system to detect and report any potential issues, such as signal degradation or antenna fouling, before they affect measurement accuracy. This proactive approach will help minimize downtime and improve overall system reliability.

Miniaturization and cost reduction

Advancements in radar technology may lead to the development of smaller, more compact radar level measurement systems. This miniaturization will make the systems easier to install in space-constrained environments and potentially reduce their overall cost, making radar measurement more accessible to a wider range of industries and applications.

Conclusion

Radar level measurement solutions offer reliable and accurate level measurements for various industries and applications. Their non-contact nature, ability to perform in challenging environments, and wide application range make them an ideal choice for many organizations. By considering factors such as process conditions, environmental factors, integration requirements, and cost-effectiveness, businesses can select the right radar level measurement solution to optimize their operations and ensure process efficiency and safety.

FAQs

1. How does radar level measurement work?

Radar level measurement works by emitting radar waves that reflect off the surface of the substance being measured and then measuring the time it takes for the waves to return. This time-of-flight principle allows the distance to the surface to be calculated accurately.

2. Can radar level measurement be used in hazardous environments?

Yes, radar level measurement can be used in hazardous environments. It is designed to withstand extreme temperatures, pressures, and corrosive or explosive atmospheres, making it suitable for applications in the oil and gas industry and other hazardous environments.

3. What is the difference between guided wave radar and non-contact radar?

Guided wave radar uses a probe or cable that extends into the substance being measured, while non-contact radar operates without physical contact with the substance. Guided wave radar is particularly useful for measuring liquids and detecting interface levels, while non-contact radar is suitable for measuring liquids, slurries, and solids with uneven or turbulent surfaces.

4. Are radar level measurement solutions expensive?

The cost of radar level measurement solutions can vary depending on factors such as the measurement range, accuracy requirements, and additional features. While radar level measurement solutions may have a higher upfront cost compared to other technologies, their long-term reliability, accuracy, and suitability for challenging environments often outweigh the initial investment.

5. Can radar level measurement solutions be integrated with existing control systems?

Yes, radar level measurement solutions can be integrated with existing control systems. They can communicate with other devices using standard protocols such as Modbus or Profibus, allowing seamless integration and data exchange for process control and automation.