What Kind of Flow Meter is Suitable for Solvents?

In industrial processes where solvents are involved, accurate measurement of flow rates is essential for maintaining efficiency and ensuring product quality. Choosing the right flow meter for solvents is crucial to prevent any potential issues such as leaks, inaccuracies, or damage to the equipment. This article will explore various types of flow meters and recommend the most suitable options for measuring solvents.

Introduction: Importance of Flow Measurement for Solvents

In industries such as chemical processing, pharmaceuticals, oil and gas, and many others, solvents play a vital role in various processes. Accurate measurement of solvent flow rates ensures precise control of mixing ratios, reaction rates, and overall process efficiency. Improper flow measurement can lead to quality issues, wastage of solvents, and even hazardous situations. Therefore, selecting the right flow meter is crucial to achieve reliable and accurate measurements.

Challenges in Measuring Solvents

Measuring solvents pose unique challenges due to their chemical properties. Solvents can vary in terms of viscosity, volatility, corrosiveness, and compatibility with different materials. These properties can affect the performance and accuracy of flow meters. Solvents with low viscosity, such as alcohols, may require a different type of flow meter compared to high-viscosity solvents like heavy oils. It is important to consider these challenges when choosing a flow meter for solvents.

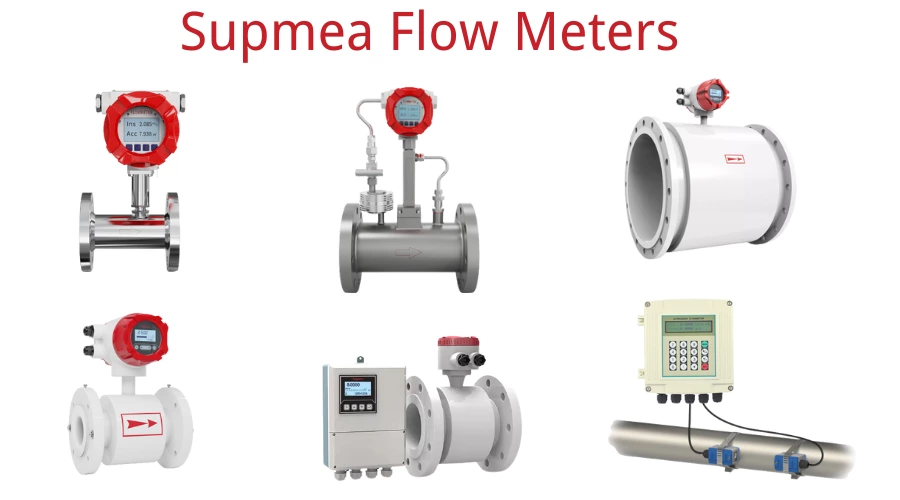

Types of Flow Meters

There are several types of flow meters available in the market, each with its own operating principles and suitability for different applications. Let's explore some commonly used flow meter types and their characteristics.

Positive Displacement Flow Meters

Positive displacement flow meters operate by dividing the fluid into specific volumes and measuring the number of times the chamber fills and empties. These meters are suitable for measuring low to moderate flow rates and are often used for viscous liquids. However, when it comes to solvents, positive displacement flow meters may face challenges due to their intricate design, which can be susceptible to solvent damage or leakage.

Turbine Flow Meters

Turbine flow meters use a rotor with blades that rotate as the fluid flows through. The rotation speed is proportional to the flow rate, allowing for accurate measurements. Turbine flow meters are commonly used for low-viscosity fluids but can encounter difficulties with solvents that have high vapor pressures or are prone to causing wear and tear on the rotor.

Magnetic Flow Meters

Magnetic flow meters, also known as electromagnetic flow meters, utilize Faraday's law of electromagnetic induction to measure flow rates. They are highly accurate and suitable for a wide range of fluids, including solvents. Magnetic flow meters do not have any moving parts in contact with the fluid, making them less prone to damage or clogging. However, they may have limitations when measuring low-conductivity solvents.

Ultrasonic Flow Meters

Ultrasonic flow meters employ sound waves to measure flow rates. They use either transit-time or Doppler methods to determine the velocity of the fluid. Ultrasonic flow meters are non-intrusive and can handle various fluid types, including solvents. However, their accuracy can be affected by the presence of bubbles or particulate matter in the solvent.

Coriolis Flow Meters

Coriolis flow meters rely on the Coriolis effect, where the fluid's momentum causes a tube to twist, producing a phase shift that is proportional to the mass flow rate. Coriolis flow meters are highly accurate and suitable for measuring solvents due to their robust design and ability to handle different fluid properties. They can handle high-viscosity solvents and offer excellent accuracy and repeatability.

Vortex Flow Meters

Vortex flow meters use the principle of fluid oscillation around a bluff body to determine the flow rate. As vortices are shed, their frequency is proportional to the fluid velocity. Vortex flow meters are suitable for various fluids, including solvents, but may encounter challenges with low flow rates or highly corrosive solvents that can degrade the bluff body over time.

Thermal Mass Flow Meters

Thermal mass flow meters measure the convective heat transfer between a heated sensor and the fluid. The heat transfer is proportional to the mass flow rate, allowing for accurate measurements. Thermal mass flow meters are suitable for low-flow applications and can handle various fluid types, including solvents. However, they may require calibration for different solvents due to variations in thermal conductivity.

Selection Criteria for Flow Meters Suitable for Solvents

When choosing a flow meter for solvents, several factors should be considered to ensure accurate and reliable measurements. Here are some key criteria to evaluate:

Chemical Compatibility

The flow meter material should be compatible with the solvent to avoid any chemical reactions or material degradation. Solvents with high corrosivity may require flow meters constructed from specialized materials resistant to corrosion.

Accuracy and Precision

The flow meter should provide the required level of accuracy and precision for the specific application. Consider the flow range, desired measurement resolution, and the overall accuracy of the flow meter.

Flow Range

Ensure that the flow meter is suitable for the expected flow rates of the solvents in your application. Some flow meters have limitations at low or high flow rates, so it is crucial to select one that covers your desired range.

Pressure and Temperature Conditions

Consider the operating pressure and temperature range of the solvents. Ensure that the selected flow meter can handle these conditions without any adverse effects on accuracy or reliability.

Maintenance and Cost Considerations

Evaluate the maintenance requirements and costs associated with the flow meter. Some flow meters may require regular calibration, cleaning, or replacement of parts. Assess the long-term costs and availability of maintenance support.

Recommended Flow Meters for Solvents

Based on the aforementioned considerations, the following flow meters are well-suited for measuring solvents:

Coriolis Flow Meters

Coriolis flow meters offer exceptional accuracy, precision, and reliability. They can handle a wide range of solvents, including high-viscosity liquids, and are not affected by changes in fluid properties. Coriolis flow meters are a popular choice for applications where precise measurement is critical.

Magnetic Flow Meters

Magnetic flow meters are highly versatile and suitable for various fluid types, including solvents. They provide accurate measurements and are less prone to damage or clogging. Magnetic flow meters are an excellent choice for solvents with moderate conductivity.

Thermal Mass Flow Meters

Thermal mass flow meters are ideal for low-flow applications involving solvents. They offer good accuracy and are relatively low-maintenance. However, it is essential to ensure proper calibration when using different solvents with varying thermal conductivities.

Conclusion

Accurate flow measurement is crucial when working with solvents in industrial processes. Selecting the right flow meter is essential to ensure reliable measurements and maintain process efficiency. Consider the chemical compatibility, accuracy requirements, flow range, pressure and temperature conditions, and maintenance factors when choosing a flow meter for solvents. Coriolis flow meters, magnetic flow meters, and thermal mass flow meters are recommended options for measuring solvents due to their accuracy, reliability, and compatibility with various fluid properties.

FAQs

Q 1: Can all flow meters be used for measuring solvents?

Not all flow meters are suitable for measuring solvents. It is important to consider factors such as chemical compatibility, viscosity, corrosiveness, and other fluid properties when selecting a flow meter for solvents.

Q 2: What is the benefit of using a Coriolis flow meter for solvents?

Coriolis flow meters offer exceptional accuracy, even with changing fluid properties. They can handle high-viscosity solvents and provide reliable measurements, making them a preferred choice for critical applications.

Q 3: Are magnetic flow meters suitable for corrosive solvents?

Magnetic flow meters are generally resistant to corrosion and can be suitable for corrosive solvents. However, it is essential to select a flow meter with appropriate lining materials to ensure compatibility with the specific solvent.

Q 4: Do thermal mass flow meters require calibration for different solvents?

Thermal mass flow meters may require calibration adjustments when measuring different solvents with varying thermal conductivities. Calibration ensures accurate measurements and compensates for any variations in fluid properties.

Q 5: Can ultrasonic flow meters handle high-viscosity solvents?

Ultrasonic flow meters can handle a wide range of fluids, including solvents. However, their accuracy may be affected by the presence of bubbles or particulate matter in high-viscosity solvents. Proper installation and maintenance are essential for optimal performance.