| Product |

Turbidity sensor |

| Model |

MIK-PTU8011 |

| Measure range |

0.01-4000 NTU |

| Indication resolution |

Less than ± 2% of the measured value, |

| |

or ± 0.1 NTU Maximax criterion |

| Pressure range |

≤0.4 MPa |

| Flow velocity |

≤2.5m/s, 8.2ft/s |

| Environment temp |

0~45℃ |

| Calibration |

Sample Calibration, Slope Calibration |

| Cable length |

Standard 10-Meter Cable, Max Length: 100 Meters |

| High voltage baffle |

Aviation Connector, Cable Connector |

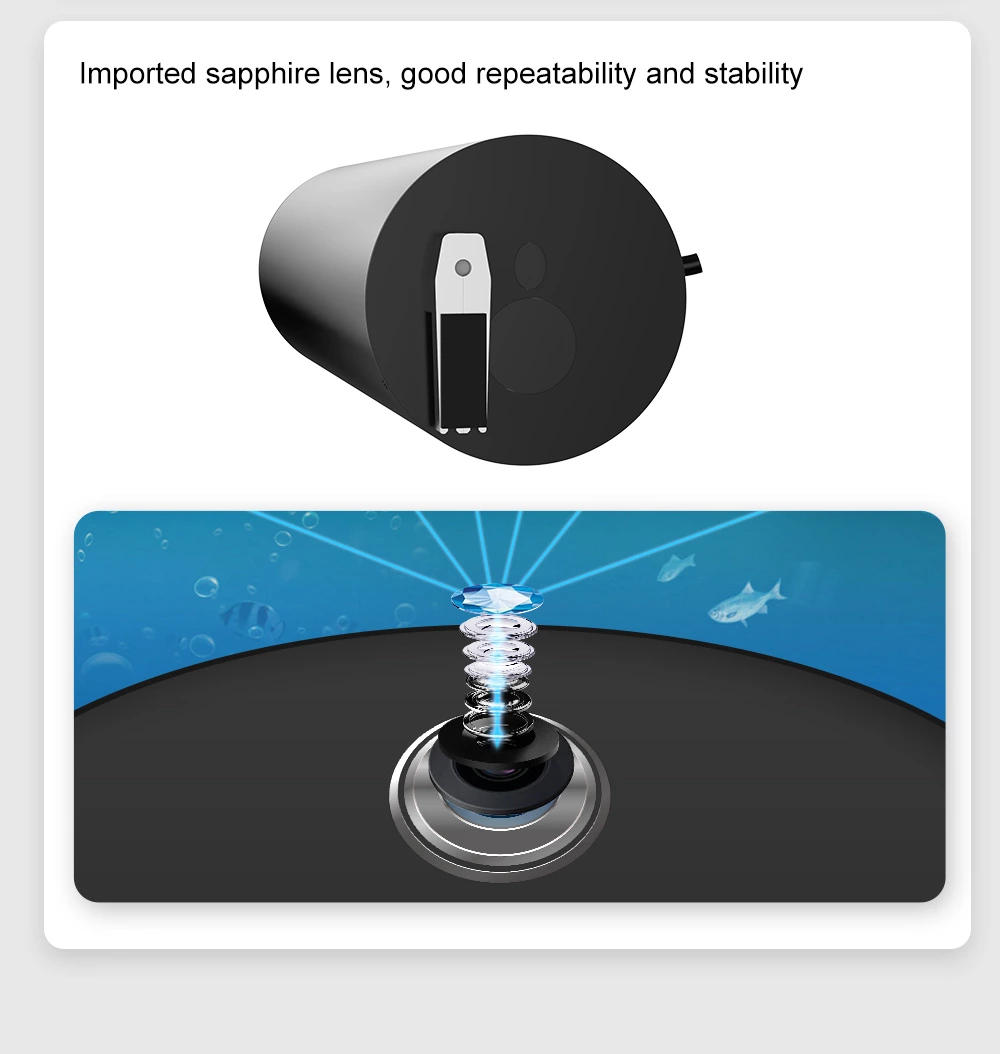

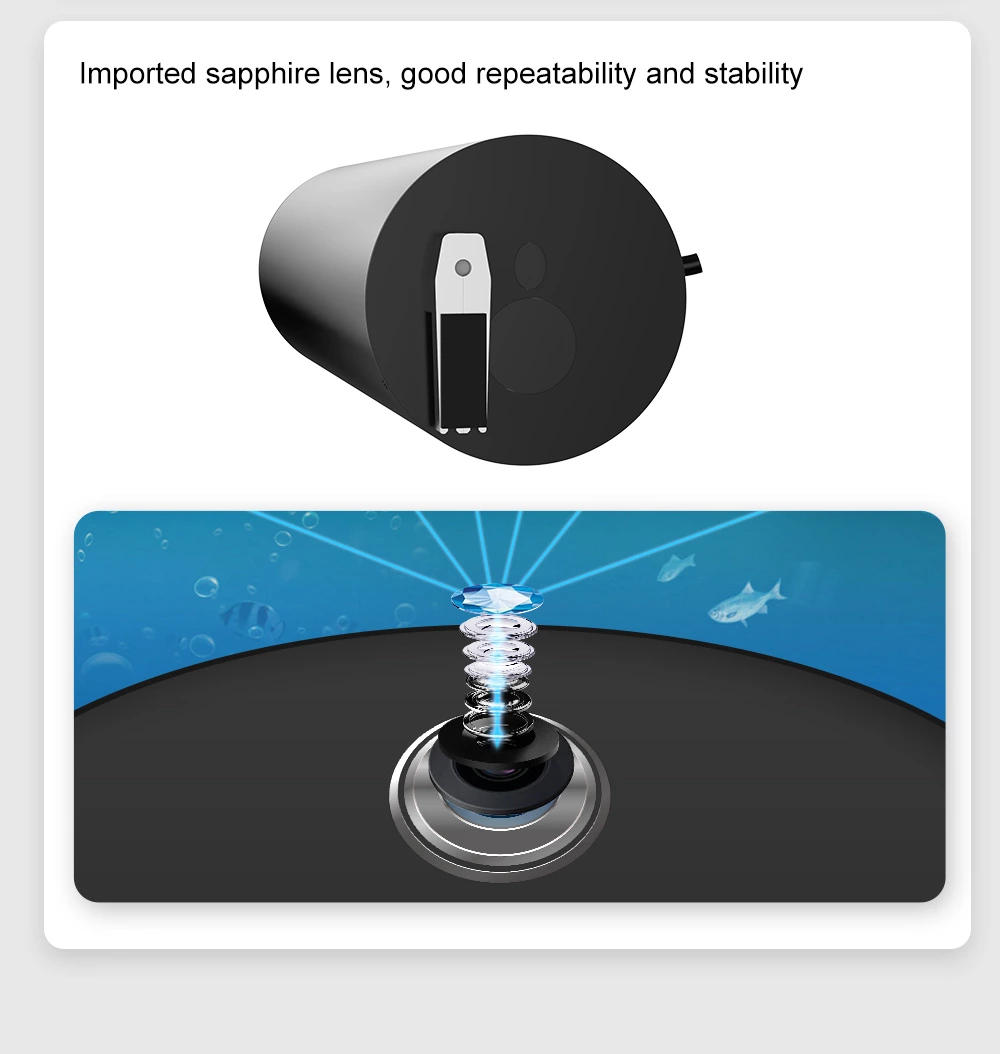

| Main materials |

Main Body:SUS316L (Ordinary Version) |

| |

Titanium Alloy (Seawater Version) |

| |

Upper and Lower Cover: POM; Cable: PUR |

| Ingress protection |

IP68/NEMA6P |

| Weight |

1.65 KG |

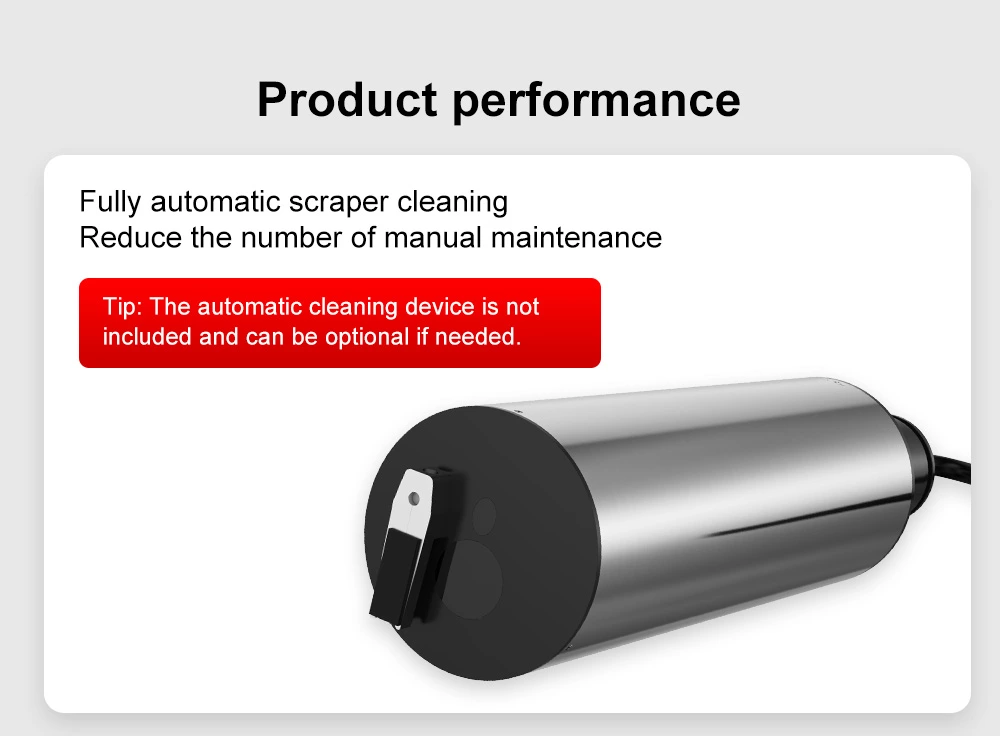

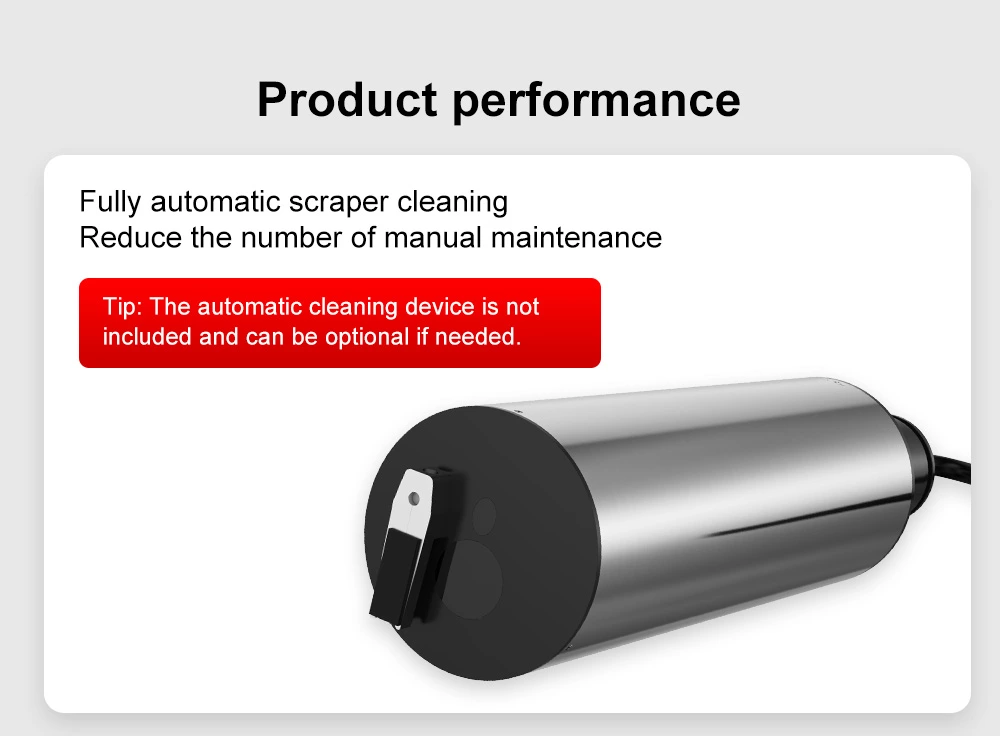

The MIK-PTU-8011 turbidity sensor is a type of process control instrument used to measure the degree of cloudiness or haziness of a liquid sample. It is commonly used in water treatment plants, food and beverage processing, and other industrial applications where water quality is critical. The key features of a turbidity sensor include its ability to detect minute particles and suspended solids in the liquid sample, and its high accuracy and sensitivity.

The main advantage of a turbidity sensor is its ability to provide real-time measurements of water quality, allowing for immediate corrective actions to be taken if the turbidity levels exceed acceptable limits. This helps to ensure that the water is safe and suitable for its intended use. Turbidity sensors also require minimal maintenance, making them a cost-effective solution for long-term monitoring of water quality.

Turbidity sensors are commonly used in water treatment plants to monitor the effectiveness of the treatment process and ensure that the water meets regulatory standards. They are also used in food and beverage processing to monitor the clarity of liquids and ensure that they are free from contaminants. In addition, turbidity sensors are used in industrial applications such as mining, where they are used to monitor the clarity of process water and ensure that it is suitable for use in the production process.