| Product |

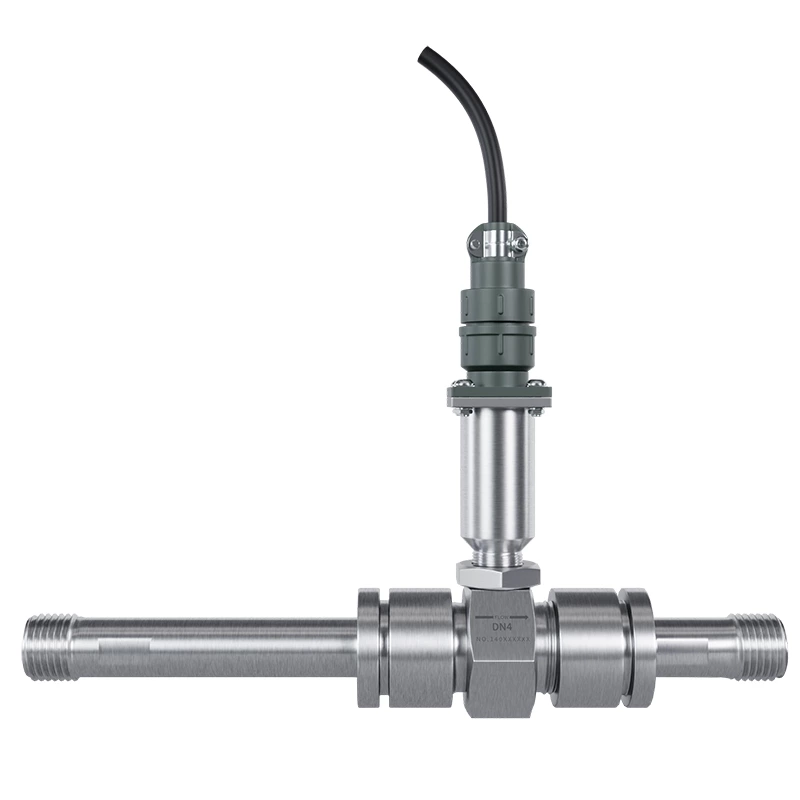

Turbine flow sensor |

| Model |

MIK-LWGY |

| Diameter Nominal |

DN4~DN100 |

| Nominal Pressure |

6.3 MPa |

| Accuracy |

0.5%R, 1.0%R |

| Medium Temperature |

-20℃~+120℃ |

| Power Supply |

3.6V lithium battery; 12 VDC; 24VDC |

| Output Signal |

Pulse, 4-20mA, RS485 (WIth transmitter) |

| Ingress protection |

IP65 |

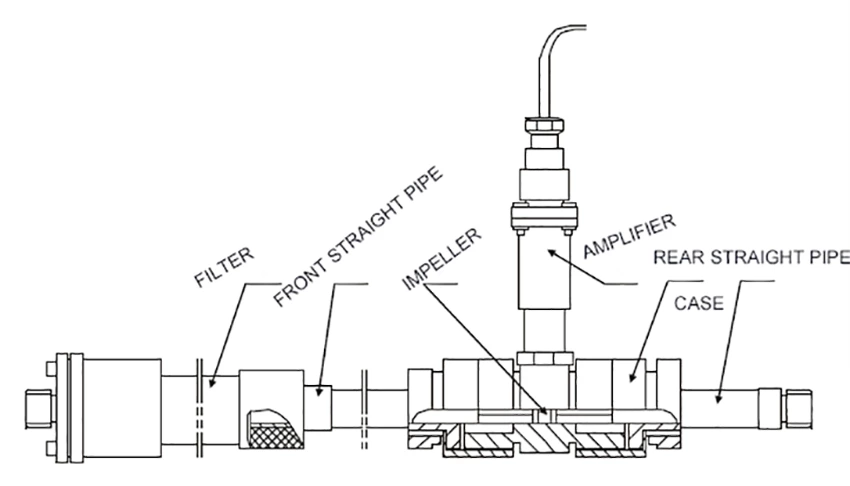

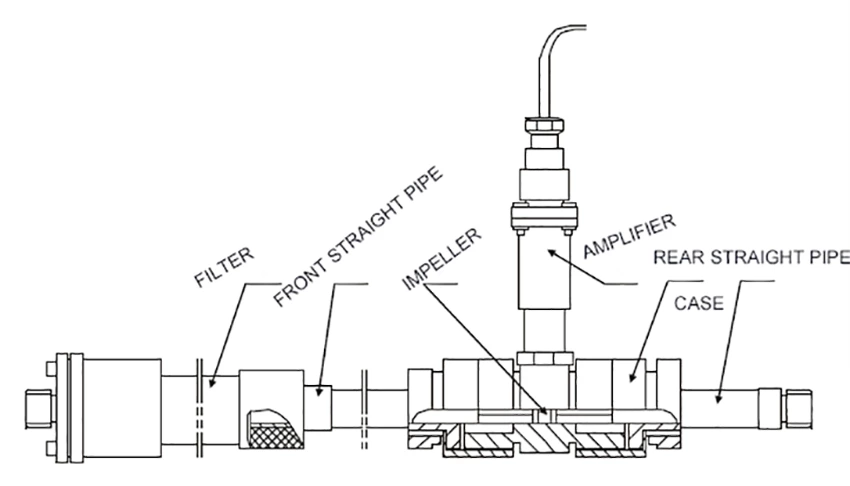

The fluid flows through the turbine flow sensor shell. Because the blade of the impeller has a certain angle with the flow direction, the impulse of the fluid makes the blade have rotation torque. After overcoming the friction torque and fluid resistance, the blade rotates. After the torque is balanced, the speed is stable. Under certain conditions, the speed is proportional to the flow rate. Because the blade has magnetic conductivity, it is in the position of the signal detector (composed of permanent magnetic steel and coil) of the magnetic field, the rotating blade cuts the magnetic line of force and periodically changes the magnetic flux of the coil, so that the electric pulse signal is induced at both ends of the coil.