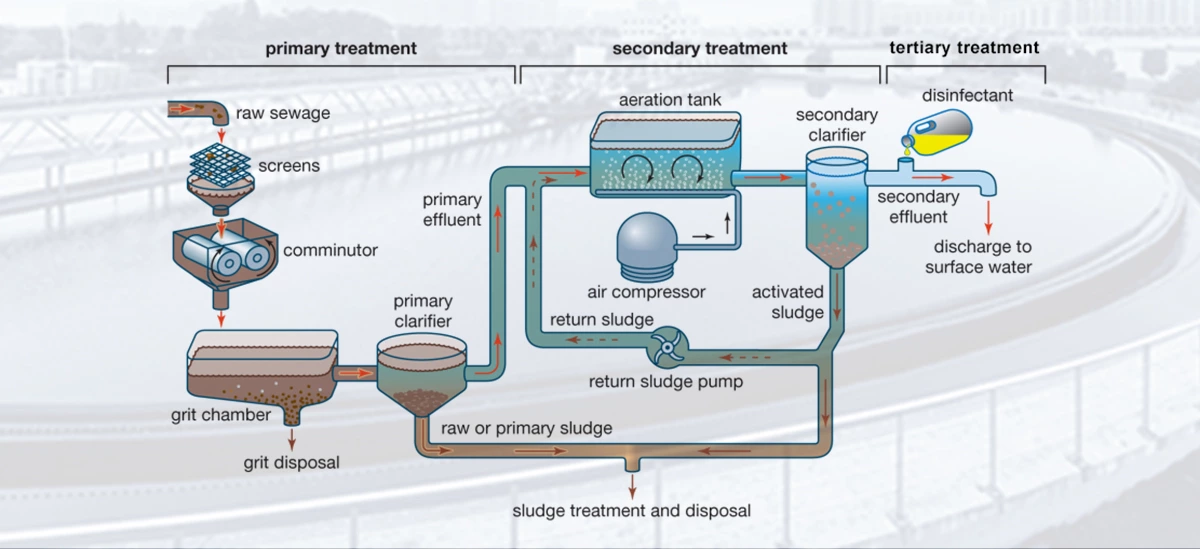

As the most important raw material in human production and a necessity in daily life, water resources are suffering unprecedented destruction with the acceleration of the industrialization process. The protection and treatment of water resources have reached an urgent situation. The pollution of water resources, mainly comes from the discharge of industrial water, as well as the massive discharge of various production and domestic sewage in cities.

At the same time, the requirements for the operation of various types of sewage treatment equipment, and the monitoring of sewage treatment water quality and water volume have also become higher.

Sewage treatment plants around the world rely on Supmea measurement technology because they place great importance on high plant availability, maintenance-free operation and accurate measurement data, as the basis for automatic control of the various process stages.

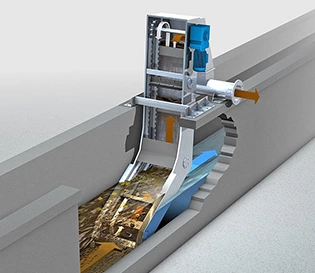

- Bar screen

A bar screen is a mechanical filter used to remove large objects, such as rags and plastics, from wastewater. It is part of the primary filtration flow and typically is the first, or preliminary, level of filtration, being installed at the influent to a wastewater treatment plant. They typically consist of a series of vertical steel bars spaced between 1 and 3 inches apart.

- Grit removal

Grit particles which are smaller than the aperture of the screen will pass through and cause abrasive problems on pipes, pumps and sludge handling equipment. The grit particles can settle in channels, aeration tank floors and sludge digestors which can create maintenance problems. Therefore, a grit removal system is required for most sewage treatment plants.

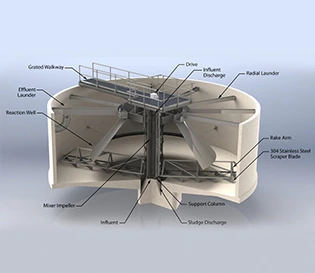

- Primary clarifiers

Clarifiers are settling tanks built with mechanical means for continuous removal of solids being deposited by sedimentation. Primary clarifiers reduce the content of suspended solids and pollutants embedded in those suspended solids

- Aerobic systems

Treatment process for raw wastewater or further polishing of pretreated wastewater Aerobic treatment is a biological wastewater treatment process that takes place in the presence of oxygen. Aerobic biomass converts organics in the wastewater into carbon dioxide and new biomass.

- Anaerobic systems

Anaerobic digestion is a process in which microorganisms convert organic matter into biogas in the absence of oxygen Anaerobic treatment is typically utilized to treat warm, high-strength industrial wastewater containing high concentrations of biodegradable organic matter. This energy-efficient process reliably removes biochemical oxygen demand (BOD), chemical oxygen demand (COD), and total suspended solids (TSS) from wastewater.

- Secondary clarifier

Clarifiers are settling tanks built with mechanical means for continuous removal of solids being deposited by sedimentation. secondary clarifiers remove flocs of biological growth created in some methods of secondary treatment including activated sludge, trickling filters and rotating biological contactors

- Disinfect

Aerobic treatment processes reduce pathogens, but not enough to qualify as a disinfection process. Chlorination/dechlorination has been the most widely used disinfection technology in the world, ozonation and UV light are emerging technologies

- Discharge

When the treated sewage meets the national or local sewage discharge standards, it can be discharged to surface water or identify opportunities to prevent or reduce wastewater pollution through such measures as recycle/reuse within their facility, input substitution.

Recommended Products

- MIK-LDG Carbon steel body electromagnetic flow meter

- MIK-LDG Remote type electromagnetic flowmeter

- MIK-PH6.3 pH/ORP meter

- MIK-DC2000 Water quality monitor (conductivity/turbidity/DO)

- MIK-MP Ultrasonic level transmitter

- WSR550 76-81GHz Radar level transmitter

- MIK-P300 Pressure transmitter